RV Deep-Cycle Battery Alternatives: A Comparative Analysis Against Lithium Iron Phosphate

Before we get into Technical data between the batteries - I know SAFETY is a concern among all RV owners and enthusiests so let’s address this first.

WHICH BATTERIES ARE CONSIDERED SAFEST AND WHY?

LiFePO4 (Lithium Iron Phosphate) batteries are generally considered the safest for RVs compared to other types of lithium-ion batteries and traditional lead-acid or AGM batteries.

Flooded Lead-Acid (FLA): These are generally considered the least safe for RV interiors due to the mandatory venting of flammable hydrogen gas during charging and the risk of spilling corrosive acid.The significance of maintenance and user practices is underscored by USFA/FEMA data (2018-2020), which identified "Unintentional actions" as the leading known cause of ignition in RV fires (36.2%). Furthermore, a large percentage of fire causes were "Undetermined after investigation" (25.6%) or remained "Under investigation" (13.4%), often because the fire damage itself obscured the origin. While "Failure of equipment or heat source" was identified in 14.7% of cases (the area most directly addressed by recalls), the data strongly suggests that factors within the owner's control—maintenance diligence and safe operating habits—are critically important in preventing a large portion of RV fires. Relying solely on the recall system provides an incomplete safety picture.

AGM and Gel: While safer than FLA (sealed, no routine gassing, spill-proof) , they can still vent hydrogen gas under fault conditions like severe overcharging. Therefore, ventilation is still often recommended if installed inside living areas.Gel batteries are particularly sensitive to overcharging, which can damage them.Know Your Rig: Key Systems That Need Your Attention.

Sodium-Ion: This emerging technology shows promise for safety, potentially having lower thermal runaway risk than even LiFePO4. However, it is not yet a widely available or mature option for RVs, primarily due to lower energy density compared to LiFePO4. Certain systems within an RV are more frequently associated with fire risks due to their function and complexity. Familiarity with these areas helps owners focus their preventative efforts.Key findings indicate distinct advantages and disadvantages for each technology in the RV context.

SUBSCRIBE 100% FREE

TECHNICAL ANALYSIS DEEP DIVE

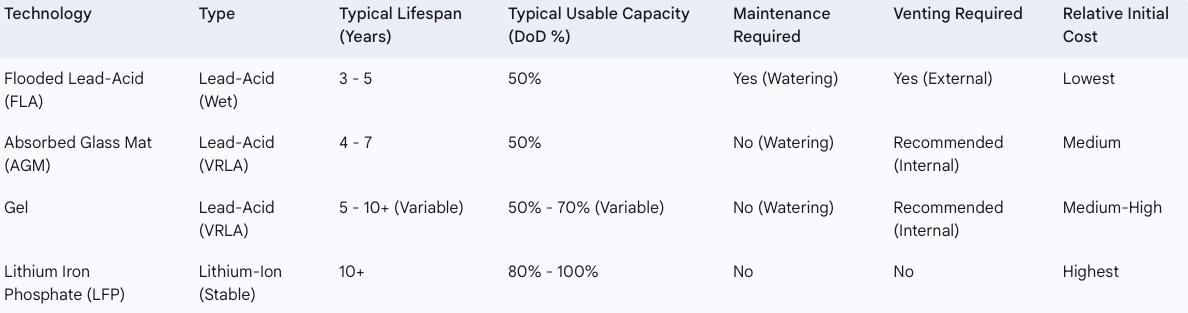

This report provides a comparative analysis of the primary alternatives to Lithium Iron Phosphate (LiFePO4) batteries for recreational vehicle (RV) power systems. The focus is on established deep-cycle lead-acid technologies: Flooded Lead-Acid (FLA), Absorbed Glass Mat (AGM), and Gel batteries. The core trade-off examined is the significantly lower initial acquisition cost associated with lead-acid variants versus the superior performance, longevity, reduced weight, and higher upfront investment required for LiFePO4 technology.

FLA batteries offer the lowest entry cost but demand the highest level of user maintenance (regular watering), are the heaviest option, necessitate external ventilation due to hydrogen gas emissions, and possess the shortest operational lifespan.

AGM batteries represent a popular middle ground, being maintenance-free (no watering), spill-proof, and capable of charging in sub-freezing temperatures (unlike standard LiFePO4), but they remain heavy, offer only moderate lifespan, and are typically limited to 50% depth of discharge (DoD) for optimal life. Gel batteries are also maintenance-free and spill-proof, demonstrating good tolerance to high temperatures and potentially longer cycle life than AGM under deep discharge conditions; however, they are highly sensitive to charging parameters, requiring slow charge rates and specific voltage profiles to avoid permanent damage.

LiFePO4 batteries (Lithium Iron Phosphate) batteries ARE GENERALLY CONSIDERED THE SAFEST for RVs compared to other types of lithium-ion batteries and traditional lead-acid or AGM batteries.

LiFePO4 batteries are known for their high stability and resistance to thermal runaway, meaning they are less likely to overheat, catch fire, or explode, even under stress. This makes them a reliable and safer choice for RV use, especially in confined spaces.consistently deliver the highest performance across key metrics including weight savings, usable energy capacity (due to high DoD tolerance), cycle life, charging speed, and energy efficiency, resulting in the lowest overall lifecycle cost despite the highest initial purchase price. Their main operational constraint is the inability of standard cells to charge below freezing temperatures without integrated heating elements or careful management. Emerging technologies, particularly Sodium-Ion, show promise for cost reduction and improved temperature range compared to LiFePO4, but as of 2025, their lower energy density presents a barrier to widespread adoption in weight and space-constrained RV applications.

Ultimately, the optimal battery choice for an RV depends on a careful evaluation of the owner's budget priorities (initial vs. long-term), typical usage patterns (weekend trips vs. full-time off-grid living), climate conditions encountered during travel, constraints on vehicle weight and storage space, and the user's technical comfort level with system requirements and potential maintenance.

The RV Power Dilemma Beyond Lithium

Modern recreational vehicles increasingly depend on capable house battery systems to power appliances, lighting, and electronics, enabling comfortable off-grid experiences. Lithium Iron Phosphate (LiFePO4) batteries have surged in popularity within the RV community, largely due to their significant performance advantages over traditional technologies, however, the considerable initial financial outlay required for LiFePO4 systems , coupled with specific operational requirements such as the need for temperature management during charging in sub-freezing conditions , prompts many RV owners to explore more established and budget-friendly alternatives.

The primary alternatives suitable for the demanding charge-discharge cycles of RV house banks are based on lead-acid chemistry. These include the traditional Flooded Lead-Acid (FLA), often referred to as "wet cell" batteries, and two types of Sealed Lead-Acid (SLA) or Valve Regulated Lead-Acid (VRLA) batteries: Absorbed Glass Mat (AGM) and Gel.

Unlike automotive starting batteries designed for short bursts of high current, these deep-cycle batteries are engineered to provide sustained power over extended periods and withstand repeated discharges to a significant percentage of their capacity.

Comparing RV Battery Technologies

Understanding the fundamental design and operational principles of each battery type is crucial for appreciating their respective strengths and weaknesses in an RV setting.

Flooded Lead-Acid (FLA)

FLA batteries represent the oldest and often most economical type of deep-cycle battery technology used in RVs. Their construction involves lead plates suspended freely within a liquid electrolyte, typically a solution of sulfuric acid and water. This design necessitates regular user maintenance; distilled water must be periodically added to individual cells to replenish electrolyte lost through evaporation and gassing during charging, preventing the plates from being exposed to air, which causes irreversible damage. FLA batteries are typically unsealed and feature vents that release hydrogen and oxygen gases generated during the charging process. Consequently, they must be installed in well-ventilated compartments, ideally external to the RV living space, and mounted upright to prevent electrolyte spillage.

Absorbed Glass Mat (AGM)

AGM batteries are a more advanced iteration of lead-acid technology, classified as Sealed Lead-Acid (SLA) or Valve Regulated Lead-Acid (VRLA). In an AGM battery, the sulfuric acid electrolyte is not free-flowing but is instead absorbed and held within highly porous microfiberglass mats sandwiched tightly between the lead plates. This immobilization of the electrolyte makes AGM batteries spill-proof and allows them to be mounted in various orientations (though upright is often still recommended). Under normal operating conditions, the oxygen and hydrogen gases produced during charging are internally recombined back into water through a chemical process facilitated by the VRLA design, eliminating the need for regular watering and rendering them "maintenance-free" in that regard. While sealed, they do possess safety valves that can release excess pressure (and potentially hydrogen gas) under fault conditions like severe overcharging.

Gel Batteries

Gel batteries are another type of SLA/VRLA technology, similar in principle to AGM but differing in the electrolyte's form. In Gel batteries, the sulfuric acid electrolyte is mixed with a silica gelling agent, transforming it into a thick, immobile, jelly-like substance. Like AGM, this design makes Gel batteries spill-proof, maintenance-free (no watering), and capable of being mounted in various orientations. They are specifically designed for deep-cycle applications and also utilize pressure relief valves for safety. Gel batteries are known for their tolerance to high temperatures and potentially longer service life in deep discharge applications compared to AGM, but they are particularly sensitive to charging parameters.

Lithium Iron Phosphate (LiFePO4 / LFP) - The Benchmark

LiFePO4 (or LFP) represents a specific and particularly safe subset of lithium-ion battery chemistry, widely adopted for RV house power systems. It utilizes lithium iron phosphate (LiFePO4) as the cathode material, which contributes to its notable thermal and chemical stability compared to other lithium-ion chemistries like Lithium Cobalt Oxide (LCO) or Nickel Manganese Cobalt (NMC) commonly found in consumer electronics. This stability significantly reduces the risk of thermal runaway (uncontrolled overheating) and makes LFP batteries inherently safer for installation within an RV. A critical component of any LFP battery is the integrated Battery Management System (BMS), an electronic circuit board that monitors and protects the individual cells within the battery from over-charge, over-discharge, over-current, short circuits, and extreme temperatures. LFP batteries require no periodic maintenance like watering and do not produce gas emissions during normal operation.

Performance Metrics Head-to-Head

Comparing these technologies requires examining key performance indicators relevant to the unique demands of RV usage, where factors like weight, usable energy, lifespan, and charging efficiency directly impact the user experience.

SUBSCRIBE 100% FREE

Energy Density, Weight, and Footprint

Energy density, the amount of energy stored per unit of weight (Wh/kg) or volume (Wh/L), is a critical metric for RVs where both space and payload capacity are limited.

LiFePO4: Offers the highest energy density among these options, typically ranging from 90-160 Wh/kg , with some advanced cells reaching towards 180-210 Wh/kg. This translates directly into significant weight savings; LFP batteries are often up to 50% lighter than AGM counterparts and can weigh as little as one-third of an equivalent lead-acid battery. A typical 100Ah LFP battery might weigh between 23-31 lbs, compared to 60-70 lbs or more for a 100Ah lead-acid battery. Consequently, LFP batteries occupy a much smaller physical footprint for the same amount of stored energy. Some analyses suggest LFP stores 3 to 4 times as much energy compared to the same size lead-acid battery.

AGM: Possesses a lower energy density, typically in the range of 50-70 Wh/kg , although some sources place it slightly lower at 30-50 Wh/kg. AGM batteries are inherently heavy due to their lead content. A 100-120Ah AGM battery commonly weighs between 64 lbs and 77 lbs.

Gel: Energy density is generally similar to or slightly lower than AGM, often cited around 30-50 Wh/kg. Gel batteries are also heavy, sometimes marginally heavier than AGM for the same nominal capacity , with estimates around 69-79 lbs for a 100Ah unit.

FLA: Exhibits the lowest energy density, although specific Wh/kg figures are less commonly cited than their obvious bulk and weight. FLA batteries are consistently the heaviest option per unit of energy stored.

The implications for RV owners are substantial. Reducing battery bank weight directly increases the available payload capacity for essential supplies like water, or for personal gear and passengers. Lighter weight can also subtly improve vehicle handling and potentially offer marginal fuel economy benefits.

For instance, replacing a bank of four 65 lb AGM batteries (totaling 260 lbs) with two 30 lb LFP batteries (totaling 60 lbs) to achieve similar usable energy yields a 200 lb weight reduction.

Furthermore, the smaller footprint of LFP batteries frees up valuable storage space within the RV. Critically, the comparison must account for usable capacity; since lead-acid batteries are typically limited to 50% DoD, an RVer needs roughly double the nominal Ah rating (and thus double the weight and volume) in lead-acid compared to LFP to achieve the same usable energy reserve. This further amplifies the weight and space advantage of LFP technology in practical application.

RV Weight and distribution changes AFTER PURCHASE matter A LOT.

PLEASE SEE our 2 articles regarding chassis and frames + suspension systems or more information.

SUBSCRIBE 100% FREE

Lifespan, Cycle Life, and Usable Capacity (DoD)

The longevity and the actual amount of energy accessible from a battery bank are paramount for RV power systems.

LiFePO4: Offers the longest operational lifespan, typically exceeding 10 years. This is supported by a very high cycle life, commonly rated between 2,000 and 7,000+ charge/discharge cycles depending on the manufacturer and usage conditions. Crucially, LFP batteries tolerate deep discharges well, with a recommended Depth of Discharge (DoD) of 80-100%. Deep discharging does not significantly impact their lifespan compared to lead-acid types.

AGM: Provides a medium lifespan, typically estimated at 4 to 7 years under optimal conditions. Cycle life is moderate, generally rated around 400-800 cycles at a 50% DoD , though some premium brands claim up to 1,200 cycles. However, cycle life is highly sensitive to the depth of discharge. For longevity, it is strongly recommended to limit discharges to a maximum of 50% DoD. While deeper discharges (up to 80%) are physically possible, they drastically reduce the battery's overall cycle count.

Gel: Lifespan estimates vary, with some sources suggesting potential for 10-20 years in ideal, stable applications.However, cycle life ratings are often similar to or slightly better than AGM, perhaps 600-1,000 cycles at 50% DoD, potentially doubling AGM's life in certain deep-cycle scenarios. Gel batteries may tolerate deeper discharges (60-70% mentioned ) better than AGM, but this still significantly reduces overall lifespan. A 50% DoD limit is often recommended for longevity.

FLA: Exhibits the shortest lifespan, typically 3 to 5 years. Cycle life is low, around 300-500 cycles at 50% DoD, and extremely sensitive to discharge depth. A maximum DoD of 50% is crucial for maximizing life.

The concept of usable capacity (Nominal Amp-hour Rating x Depth of Discharge percentage) is far more relevant for RV energy planning than the nominal rating alone. LiFePO4 batteries offer nearly double the usable energy per rated Amp-hour compared to lead-acid batteries constrained by the 50% DoD recommendation. This fundamental difference means an RVer can install fewer LFP batteries (or smaller capacity ones) to achieve the same usable energy reserve as a much larger, heavier lead-acid bank, directly impacting system cost, weight, and space requirements.

Furthermore, the 50% DoD limitation inherent in lead-acid technologies effectively means that half of the battery's nominal capacity represents "dead weight" – mass and volume carried by the RV that cannot be regularly accessed without significantly shortening the battery's life. A 200Ah AGM bank provides only 100Ah of usable energy routinely , whereas a 100Ah LFP battery delivers 80-100Ah. This inefficiency in utilizing the installed capacity is a key disadvantage of lead-acid compared to LFP.

Additionally, cycle life ratings are typically based on ideal laboratory conditions. Real-world RV usage involves fluctuating temperatures, variable discharge depths depending on appliance use, and potentially incomplete charging cycles. Lead-acid batteries, particularly sensitive to deep discharges, may experience a much shorter actual lifespan in such variable conditions if the 50% DoD limit is frequently exceeded. LiFePO4's inherent tolerance for deeper discharges makes it more robust and forgiving in the face of unpredictable RV power demands, potentially allowing it to achieve a service life closer to its rated specifications in practice.

Maintenance and Safety Considerations

Operational requirements and safety are critical factors for components installed within the confined space of an RV.

LiFePO4: Requires no routine maintenance. They do not produce gas emissions during normal operation, eliminating the need for venting. The LFP chemistry is inherently stable, posing a very low risk of thermal runaway, fire, or explosion compared to other lithium-ion types. Safety is further enhanced by the mandatory internal BMS, which provides multiple layers of protection against operational faults.

AGM: Considered maintenance-free as they do not require periodic watering. Being sealed and spill-proof allows flexible mounting. The VRLA design aims to recombine charging gases internally, but under conditions like overcharging or high temperatures, the safety valves can release hydrogen gas. Therefore, proper ventilation is still recommended, especially if installed within the RV's living area, to prevent potential gas accumulation.AGM batteries are generally more resistant to vibration damage than FLA batteries. They are, however, sensitive to overcharging, which can lead to drying out and premature failure.

Gel: Also maintenance-free regarding watering and spill-proof due to the gelled electrolyte. Like AGM, they are sealed with safety valves that can vent gas under pressure. Gel batteries are extremely sensitive to charging parameters; using incorrect voltage settings or attempting fast charging can cause gas bubbles to form permanent voids within the gel, irreversibly damaging the battery. Their internal structure can be more fragile than AGM.

FLA: Demand the most user intervention, requiring regular checks of electrolyte levels and addition of distilled water. They must be installed upright to avoid spilling corrosive sulfuric acid. During charging, they actively vent flammable hydrogen gas, mandating installation in a dedicated, externally vented battery box away from living quarters and potential ignition sources. There is an inherent risk of acid spills and corrosion of surrounding components. FLA batteries are also more susceptible to internal damage from vibration compared to sealed types.

SUBSCRIBE 100% FREE

From a practical standpoint, the maintenance burden of FLA batteries can be significant for RV owners. While AGM and Gel batteries eliminate the need for watering, the term "maintenance-free" can be misleading. Users must remain vigilant about employing the correct charging profiles and voltages to prevent damage, particularly with Gel batteries.LiFePO4, protected by its sophisticated BMS, generally requires less user oversight regarding charging specifics (assuming compatible charging sources are used), shifting the focus from physical upkeep to ensuring system compatibility.

Safety within the confined environment of an RV is non-negotiable. The potential for hydrogen gas accumulation from lead-acid batteries (especially FLA, but possible with AGM/Gel under fault conditions) presents a significant hazard if venting is inadequate or fails. LiFePO4's absence of off-gassing during normal operation, combined with the inherent stability of the LFP chemistry, provides a distinct safety advantage, particularly for installations inside the main cabin.

Charging Dynamics: Speed, Efficiency, and Sensitivity

How quickly and efficiently batteries can be recharged significantly impacts off-grid capability and convenience.

LiFePO4: Offers the fastest charging capabilities. LFP batteries can typically accept very high charge currents, often rated at 0.5C to 1C (meaning a 100Ah battery could potentially be charged at 50A to 100A). This allows for rapid recharging, with full charge times ranging from 1-3 hours to 2-6 hours or around 5 hours depending on the charger and battery size. Charge efficiency is very high, typically 95% or greater (up to 98%) , meaning less energy is wasted as heat during the process. A key advantage is that LFP maintains high charge acceptance until nearly full, largely bypassing the slow "absorption" charging phase characteristic of lead-acid batteries. However, a critical limitation is that standard LFP cells cannot be safely charged below freezing (0°C / 32°F) without risking permanent damage (lithium plating). Specialized low-temperature versions with built-in heaters are available but add cost.

AGM: Charges faster than FLA or Gel batteries. Typical recharge time from 50% DoD is estimated at 4-8 hours , with total charge times often exceeding 5 hours. Charge efficiency is moderate, generally around 80-85% , although higher figures are sometimes claimed. AGM batteries exhibit a slower absorption charging phase for the final 10-20% of charge. They are sensitive to overcharging, which can cause damage. A key advantage over standard LFP is their ability to accept a charge in sub-freezing temperatures, although efficiency is reduced.

Gel: Characterized by slow charging requirements. Recharge times are the longest, ranging from 5-10 hours from 50% DoD to 8-16 hours for a full charge. Efficiency is comparable to AGM, around 85-90%. Gel batteries are highly sensitive to charge rate and voltage; they cannot tolerate fast charging and require chargers with specific Gel profiles to prevent damage. Like AGM, they can be charged below freezing.

FLA: Charging is slow, similar to Gel batteries , with typical full charge times of 8-16 hours. Efficiency is the lowest, often around 80% or less. They also have a lengthy absorption phase to reach full charge. FLA batteries are prone to damage from sustained overcharging and can be charged below freezing.

The practical benefits of faster charging, as offered by LiFePO4, are significant for RVers. It translates to shorter generator run times, saving fuel and reducing noise pollution, and allows for more effective capture of energy from solar panels during limited daylight hours. Higher charge efficiency means less energy input is required to replenish the battery, making the entire power system more effective. The slow absorption phase of lead-acid batteries is a notable drawback in typical RV usage cycles, where charging sources (solar, alternator, generator) may not run long enough to fully complete this stage. Consistently leaving lead-acid batteries in a partial state of charge accelerates sulfation (the formation of lead sulfate crystals on the plates), which reduces capacity and shortens lifespan. Gel batteries' extreme sensitivity to charging parameters necessitates careful charger selection and configuration, adding complexity for the user.

These charging dynamics directly influence off-grid autonomy. An RVer relying heavily on solar power benefits greatly from LiFePO4's ability to quickly absorb available energy during peak sun hours. Slower charging lead-acid batteries might struggle to fully recharge daily, especially on cloudy days or during seasons with shorter daylight, potentially leading to a gradual depletion of reserves or increased reliance on generator power. Conversely, the inability of standard LiFePO4 batteries to accept a charge below 0°C (32°F) poses a significant challenge for winter camping if charging from solar or the vehicle's alternator is required, unless batteries with integrated heating systems are utilized.

Temperature Resilience and Limitations

RV batteries must perform reliably across a range of ambient temperatures encountered during travel.

LiFePO4: Generally offers a wide discharge temperature range, commonly cited as -20°C to 60°C (-4°F to 140°F). LFP chemistry performs well in hot conditions and exhibits better cycle life retention at elevated temperatures compared to lead-acid. The primary limitation is the charging temperature: standard LFP cells cannot be charged below 0°C (32°F) due to the risk of lithium plating on the anode, which causes irreversible damage. Heated LFP batteries are available to overcome this limitation. While discharge is possible in cold, performance (capacity/voltage) can be reduced at very low temperatures without heating.

AGM: Exhibits good overall temperature tolerance. The discharge range is often similar to LFP, potentially wider at the cold end (operational down to -40°C mentioned , though typical charge/discharge limits are often -20°C to 50°C / -4°F to 122°F ). AGM's key advantage is its ability to accept a charge below freezing (0°C / 32°F), albeit with reduced efficiency, making it simpler for cold-weather charging compared to standard LFP.However, AGM batteries are less tolerant of high heat regarding long-term degradation compared to Gel or LFP.Manufacturers often recommend halting charge if the battery core temperature reaches approximately 49°C (120°F).

Gel: Known for having the best heat tolerance among lead-acid types, maintaining performance and degrading slower in hot climates. They operate over a wide temperature range (e.g., -40°C to 65°C / -40°F to 149°F mentioned for operation , but charging is typically restricted to 0°C to 40°C / 32°F to 104°F ). Performance in extreme cold may be worse than AGM due to the thickening of the gel electrolyte, which increases internal resistance. Gel batteries are generally considered freeze-resistant.

FLA: Operates over a broad temperature range, similar to other lead-acid types (e.g., -40°C to 55°C / -40°F to 131°F). FLA batteries can also be charged below freezing. However, they are vulnerable to physical damage (case cracking) if allowed to freeze in a discharged state, as the electrolyte contains more water. High temperatures accelerate electrolyte evaporation (requiring more frequent watering) and hasten degradation.

For typical RV travel encompassing moderate climates, LiFePO4 generally offers excellent temperature performance, particularly considering the heat that can build up in battery compartments. The critical decision point revolves around the 0°C (32°F) charging limitation. If frequent charging in sub-freezing conditions is anticipated, AGM presents a simpler solution than standard LFP. Gel's superior heat tolerance might be advantageous in consistently hot desert environments, but its significant charging drawbacks often make it less practical for general RV use. FLA is reasonably robust across temperatures but requires vigilance against freezing when discharged and suffers accelerated aging in heat.

It's important to recognize that temperature influences more than just immediate operation; it significantly impacts long-term battery health and charging requirements. Elevated temperatures accelerate the chemical degradation processes in all battery types, leading to reduced capacity and shorter cycle life.

Lead-acid batteries, especially FLA and AGM, tend to degrade faster in heat compared to LiFePO4. Optimal charging for lead-acid batteries ideally involves temperature compensation – adjusting the charge voltage based on the battery's temperature to prevent over- or under-charging, which is particularly important in the variable temperature environments found in RVs. While LiFePO4 BMS typically includes temperature monitoring for protection, prolonged exposure to extreme heat will still shorten the battery's lifespan. The necessity for heated LFP batteries for reliable charging in winter adds an extra layer of cost and system complexity for cold-climate RVers.

SUBSCRIBE 100% FREE

Economic Analysis: Initial vs. Long-Term Cost

Cost is often a primary driver in battery selection, but a comprehensive analysis must look beyond the initial purchase price.

LiFePO4: Carries the highest upfront cost. Initial cost per kilowatt-hour (kWh) of nominal capacity can be around $530 or range from $250 to over 400dependingonbrandandfeatures.[11,36,47]However,duetoitsvastlysuperiorlifespan,highusablecapacity(DoD),andefficiency,LiFePO4consistentlyoffersthelowestlifecyclecost,oftenexpressedascostperusablekWhdeliveredoverthebattery′slife(/kWh/cycle or Total Cost of Ownership - TCO). Lifecycle cost estimates are around $0.15 to $0.19 per usable kWh per cycle.When comparing cost per usable Amp-hour, LFP can be cheaper than AGM even initially in some analyses.

AGM: Offers a moderate initial cost, significantly lower than LiFePO4 but typically higher than FLA. Initial cost per nominal kWh is estimated around $221. Due to its shorter lifespan and limited usable capacity, its lifecycle cost is considerably higher than LiFePO4 , estimated at roughly $0.71 per usable kWh per cycle. Cost per usable Ah is generally higher than LFP over the long term.

Gel: Initial cost is often higher than AGM but lower than LiFePO4. Lifecycle cost might be lower than AGM in applications involving frequent deep cycling ($0.25-$0.45/kWh cycle cited ), but remains higher than LiFePO4.

FLA: Boasts the lowest initial purchase price. However, its short lifespan, high maintenance needs, and limited usable capacity likely result in the highest overall lifecycle cost, although specific comparable $/kWh/cycle figures are less frequently published, it's implied to be higher than AGM.

The economic decision often boils down to the RVer's budget horizon and usage intensity. Lead-acid options provide immediate cost savings but necessitate more frequent replacements (typically 2-3 times or more during the lifespan of one LFP bank) and incur ongoing costs related to maintenance (FLA) or performance limitations (weight, usable capacity). LiFePO4 represents a significant upfront investment but delivers substantial long-term value through its extended service life, superior performance, and reduced replacement frequency. The most accurate financial comparison involves calculating the cost per usable kWh delivered over the expected lifespan of each battery type.

A true Total Cost of Ownership (TCO) analysis should also consider associated system and operational factors. Migrating to LiFePO4 might necessitate upgrading the RV's converter/charger to ensure compatibility and optimal charging, and potentially adding a DC-to-DC charger for proper alternator charging, adding to the initial investment.Conversely, the significant weight of lead-acid banks could negatively impact fuel consumption or even necessitate vehicle suspension upgrades. FLA batteries require ongoing expenditure of time and materials (distilled water) for maintenance. The labor and hassle involved in replacing heavy lead-acid batteries multiple times over the years should also be factored in, compared to the potentially single installation of an LFP bank.

Detailed Performance Metrics Comparison

Pros and Cons Analysis for RV Application

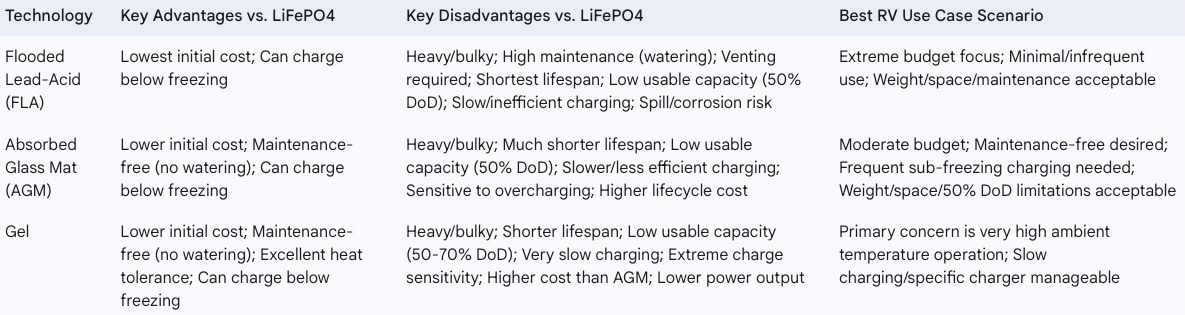

Evaluating these technologies specifically through the lens of RV usage highlights their practical advantages and disadvantages relative to the LiFePO4 benchmark.

FLA vs. LiFePO4

FLA Advantages:

Lowest Initial Cost: Significantly cheaper to purchase upfront than any other option.

Availability: Widely available at auto parts stores, battery suppliers, and big-box retailers.

Mature Technology: Well-understood, long-established technology.

Cold Charging: Can be charged in sub-freezing temperatures.

FLA Disadvantages:

Weight and Bulk: The heaviest and largest option for a given amount of usable energy.

High Maintenance: Requires frequent electrolyte level checks and topping off with distilled water.

Mandatory Venting: Produces flammable hydrogen gas during charging, requiring safe, external ventilation.

Spill/Corrosion Risk: Liquid electrolyte can spill if tipped, and acid fumes can cause corrosion.

Short Lifespan: Lowest cycle life and shortest overall service life.

Limited Usable Capacity: Restricted to ~50% DoD to maximize lifespan.

Slow & Inefficient Charging: Long recharge times and significant energy loss during charging.

Voltage Sag: Output voltage drops noticeably as the battery discharges.

Vulnerability: Susceptible to damage from vibration and freezing when discharged.

AGM vs. LiFePO4

AGM Advantages:

Lower Initial Cost: More affordable upfront than LiFePO4.

Maintenance-Free (Watering): Sealed design eliminates the need for adding water.

Spill-Proof & Flexible Mounting: Can be mounted in various orientations without leaking.

Cold Charging Capability: Can accept a charge below freezing, unlike standard LiFePO4.

Vibration Resistance: More durable against vibration compared to FLA.

Faster Charging (vs. FLA/Gel): Recharges more quickly than other lead-acid types.

Proven Technology: Widely used and well-established in RVs.

Dual-Purpose Potential: Some AGM models can serve for both deep cycling and engine starting.

AGM Disadvantages:

Heavy and Bulky: Significantly heavier and larger than LFP for the same usable energy.

Shorter Lifespan: Considerably fewer cycles and shorter service life compared to LFP.

Limited Usable Capacity: Typically restricted to 50% DoD for optimal life.

Slower & Less Efficient Charging: Takes longer to charge and wastes more energy as heat compared to LFP.

Sensitivity to Overcharging: Can be permanently damaged by excessive charge voltage.

Higher Lifecycle Cost: More expensive over the long term due to shorter life and lower usable capacity.

Potential Venting: Can release hydrogen gas under fault conditions, requiring ventilation considerations.

Voltage Sag: Output voltage drops significantly at lower states of charge.

Gel vs. LiFePO4

Gel Advantages:

Lower Initial Cost: Cheaper upfront than LiFePO4, though often pricier than AGM.

Maintenance-Free (Watering): Sealed design requires no watering.

Spill-Proof & Flexible Mounting: Can be installed in various orientations.

Excellent Heat Tolerance: Performs better and degrades slower in high temperatures compared to other lead-acid types.

Potentially Longer Cycle Life (vs. AGM): May offer more cycles than AGM, especially when deeply discharged.

Deep Discharge Tolerance (vs. AGM): May handle deeper discharges better than AGM, though still detrimental to overall life.

Low Self-Discharge: Retains charge well during storage.

Cold Charging: Can be charged below freezing.

Gel Disadvantages:

Heavy and Bulky: Significantly heavier and larger than LFP.

Shorter Lifespan: Considerably fewer cycles and shorter service life than LFP.

Limited Usable Capacity: Typically limited to 50% DoD, perhaps slightly more, but deep discharge reduces life.

Very Slow Charging: Requires slow charge rates and takes the longest to recharge.

Lower Efficiency: Less efficient charging compared to LFP.

Extreme Charging Sensitivity: Easily damaged by incorrect charge voltage or fast charging; requires specific Gel charger profile.

Higher Cost (vs. AGM): Often more expensive initially than AGM batteries.

Lower Power Output: Higher internal resistance limits ability to deliver high current compared to AGM or LFP.

Potential Venting: Can release gas under pressure/fault conditions.

SUBSCRIBE 100% FREE

Emerging Battery Horizons for RVs (circa 2025)

The search continues for battery technologies that can offer improved performance, lower cost, enhanced safety, or better resource sustainability compared to current options. While many chemistries are under development, only a few show near-term potential relevant to the RV market.

Sodium-Ion (Na-ion) Batteries

Sodium-ion technology is arguably the most prominent emerging alternative gaining traction in 2025. Positioned as a potential near-term competitor to lithium-ion, particularly the LFP variant used in RVs, Na-ion is seeing increased research, investment, and initial commercial production. Regulatory bodies have recognized its emergence by assigning new UN numbers for transportation effective in 2025 , and the first sodium-ion starting battery designed for marine use (similar demands to RV starting) has become commercially available.

Potential Advantages for RVs:

Lower Material Cost: Sodium is vastly more abundant and cheaper than lithium (estimated $0.05/kg for sodium vs. $15/kg for lithium), potentially leading to lower battery prices as production scales.

Resource Availability & Sustainability: Reduces reliance on geographically concentrated and sometimes ethically challenging sources of lithium, cobalt, and nickel.

Excellent Temperature Performance: A key advantage is the ability to operate effectively at very low temperatures (down to -40°C reported ) and, crucially, to accept a charge in sub-freezing conditions without the risk of damage inherent in standard LFP batteries.

Deep Discharge Tolerance: Early indications suggest Na-ion batteries may tolerate very deep discharges, potentially down to zero volts, without sustaining damage.

Safety: Generally considered a safe chemistry with low risk of thermal runaway.

Manufacturing Compatibility: Utilizes manufacturing processes similar to existing lithium-ion production lines, potentially facilitating faster scale-up.

Current Disadvantages for RVs:

Lower Energy Density: This is the most significant hurdle for RV applications. Current Na-ion energy densities (typically 100-150 Wh/kg, potentially reaching 200 Wh/kg) are lower than LFP (often 90-160+ Wh/kg) and significantly lower than higher-energy lithium-ion chemistries (150-250 Wh/kg). This translates directly to heavier and bulkier batteries for the same energy storage capacity, conflicting with RV constraints.

Lower Cycle Life: Current data suggests Na-ion cycle life may be lower than LFP (e.g., 1,500 cycles cited for a starting battery , though research targets higher numbers ).

Market Immaturity: As an emerging technology, product availability is limited, especially for deep-cycle RV-specific formats. Real-world performance data in RV applications is scarce.

Cost Parity Not Guaranteed: While material costs are lower, achieving overall cost parity with mature LFP production depends on manufacturing scale and technological advancements. The first available marine Na-ion battery is priced competitively with dual-purpose LFP, not significantly cheaper.

Viability Summary (2025): Sodium-ion batteries hold considerable promise, particularly due to their cost potential and superior low-temperature charging capabilities. However, their current lower energy density makes them less suitable for mainstream RV house battery applications where minimizing weight and volume is crucial. They are worth monitoring closely, as improvements in energy density could make them a compelling alternative in the future, or they might find niche RV roles where weight is less critical or cold-weather charging is paramount.

Other Technologies

Several other battery chemistries are under development, but their relevance to RVs in the near term (2025) is limited:

Lead-Carbon: This represents an enhancement of traditional lead-acid technology, incorporating carbon additives to the negative plates. The goal is to improve charge acceptance, reduce sulfation (especially during partial state-of-charge operation common with solar charging), and potentially extend cycle life compared to standard FLA or AGM batteries. While offering incremental improvements, lead-carbon batteries still carry the fundamental weight and energy density limitations of lead-acid chemistry and do not match the performance of LFP.

Saltwater Batteries: Often referring to aqueous ion batteries (including some sodium-ion variants using water-based electrolytes ), these are promoted for their potential safety and environmental benefits (using non-flammable electrolytes and abundant materials). However, they currently suffer from lower energy density and efficiency, particularly in cold temperatures, making them unsuitable for mobile RV applications and primarily targeted at stationary grid storage.

Zinc-Based, Iron-Air, Flow Batteries (e.g., Zinc-Bromine): These chemistries are being explored primarily for large-scale stationary energy storage due to factors like low cost potential (Iron-Air, Zinc) or very high cycle life (Flow Batteries). Their current energy density, power output characteristics, or system complexity generally make them impractical for RV use.

Solid-State Batteries: These promise higher energy density, improved safety (using a solid electrolyte instead of flammable liquid), and potentially longer lifespan. However, significant challenges remain in manufacturing cost, scalability, and achieving consistent performance, particularly at varying temperatures. While a long-term goal for electric vehicles, practical solid-state batteries for RV applications are not expected in the 2025 timeframe.

Graphene Batteries: Graphene is often discussed as an additive to improve existing chemistries (e.g., enhancing conductivity or lifespan) or as a component in novel battery designs. While research shows potential for faster charging and higher performance, commercially viable graphene-based batteries suitable for RVs are still in developmental stages.

Viability Summary (Other Tech): Apart from potential incremental gains from lead-carbon additives, none of these other emerging technologies appear poised to offer a practical, mainstream alternative to LFP or established lead-acid types for RV house batteries within the 2025 timeframe. Their limitations in energy density, cost, maturity, or suitability for mobile applications currently outweigh their potential benefits for this specific use case.

SUBSCRIBE 100% FREE

Conclusion and Recommendations

The selection of an RV house battery involves navigating a complex set of trade-offs between initial cost, long-term value, performance, weight, space, maintenance, and operational requirements. This analysis confirms that while traditional lead-acid technologies (FLA, AGM, Gel) offer lower upfront purchase prices, they come with significant compromises compared to Lithium Iron Phosphate (LiFePO4). These include substantially greater weight and volume per unit of usable energy, drastically shorter lifespans, limitations on usable capacity (typically 50% DoD), slower and less efficient charging, and, in the case of FLA, mandatory maintenance and ventilation requirements.

Within the lead-acid family, AGM batteries strike a balance that makes them a popular choice for RVers seeking a maintenance-free (no watering) option at a moderate cost, especially if reliable charging in sub-freezing temperatures is needed without resorting to heated LFP batteries. However, the fundamental 50% DoD limitation remains a major constraint on usable energy and contributes to their poor weight/space efficiency compared to LFP. Gel batteries offer superior heat tolerance but are hampered by slow charging requirements and extreme sensitivity to incorrect charging profiles, limiting their practicality for general RV use. FLA remains the entry-level budget option, suitable only when cost is the absolute primary driver and the significant drawbacks are deemed acceptable.

LiFePO4 technology, despite its higher initial investment, delivers demonstrably superior performance in nearly every metric relevant to RV applications: highest usable energy density (leading to lowest weight and smallest footprint), longest lifespan (by a factor of 5-10x or more), tolerance for deep discharge (80-100% DoD), fastest and most efficient charging, and inherent safety advantages (no off-gassing, stable chemistry). These factors contribute to a significantly lower total cost of ownership over the battery's extended lifespan. The primary operational challenge remains the inability of standard LFP cells to charge below freezing, requiring mitigation strategies (heated batteries, internal placement, charge management) for cold-weather campers.

Guidance for Decision-Making:

The optimal choice depends heavily on individual circumstances and priorities:

Choose Flooded Lead-Acid (FLA) if: Budget is severely constrained above all else, power demands are minimal, RV usage is infrequent, ample weight capacity and ventilated storage space are available, and the owner is willing and able to perform regular maintenance (watering).

Choose Absorbed Glass Mat (AGM) if: A moderate budget is available, a maintenance-free (no watering) solution is strongly preferred, frequent charging in temperatures below 0°C (32°F) is expected (and heated LFP is not desired), and the significant weight, space, and 50% usable capacity limitations are acceptable compromises. Often suitable for weekend or occasional RV users.

Choose Gel if: Operation in consistently very high ambient temperatures is the overriding concern, deep discharges are anticipated (though still detrimental), and the very slow charging speeds and need for precise charge control are manageable. Generally less suitable for typical varied RV usage compared to AGM or LFP.

Choose Lithium Iron Phosphate (LiFePO4) if: Long-term value, maximizing usable energy storage, minimizing weight and space, achieving fast and efficient charging, and obtaining the longest possible service life are the main goals. Ideal for frequent off-grid use, boondocking, supporting larger electrical loads (inverters, etc.), and users prioritizing performance and convenience. Requires a higher initial budget and careful consideration of cold-weather charging strategies if applicable.

Final Thoughts:

When comparing battery options, RV owners should look beyond nominal Amp-hour ratings and initial price tags. Evaluating usable capacity (Ah rating multiplied by recommended DoD percentage) provides a true measure of available energy. Calculating the lifecycle cost (total cost divided by total usable energy delivered over the battery's life, reveals the most accurate long-term economic value. Compatibility with the existing or planned RV charging system (converter, solar charge controller, alternator charging method) is also crucial. While emerging technologies like Sodium-Ion offer exciting possibilities for the future, particularly regarding cost and temperature range, they are not yet optimized for the energy density demands of most RV applications in 2025. The best battery decision ultimately aligns the chosen technology's specific characteristics with the RVer’s unique needs, travel style, and budget reality.

Pros and Cons Summary vs. LiFePO4

I hope you found our comprehensive Guide Useful. We have many others on our main site and hope you will check us out further.

If we have earned your respect and trust and you would like to subscribe and follow? It is 100% FREE.

Don’t forget to hit the heart and share if you found REAL value.

WE ALWAYS look forward or recommendations on substack! If you feel we are complimentary rather than competitive, and offer high enough quality to be worthy of that placement of course.

Sources:

https://www.usfa.fema.gov/downloads/pdf/statistics/v23i1.pdf https://www.nfpa.org/-/media/Files/News-and-Research/Fire-statistics-and-reports/US-fire-problem/Fire-causes/osrv.ashx https://batteryuniversity.com/article/bu-201-how-do-lithium-ion-batteries-work https://batteryuniversity.com/article/bu-205-types-of-lithium-ion https://batteryuniversity.com/article/bu-403-charging-lead-acid https://www.power-sonic.com/blog/lithium-iron-phosphate-lifepo4-vs-lead-acid/ https://www.trojanbattery.com/product/t-105/ https://www.lifelinebatteries.com/wp-content/uploads/2021/08/GPL-31T-AGM-Marine-RV-Deep-Cycle-Battery.pdf https://battlebornbatteries.com/product/battle-born-100ah-12v-lifepo4-deep-cycle-battery/ https://www.sciencedirect.com/topics/engineering/energy-density https://www.sciencedirect.com/science/article/pii/S2352152X2200332X https://www.energy-storage.news/an-introduction-to-sodium-ion-batteries/ https://navitassys.com/navitas-systems-launches-altrarax-the-worlds-first-sodium-ion-12v-battery-at-the-2024-miami-international-boat-show/ https://unece.org/transport/dangerous-goods/unscetdg-63-dec-2023 https://www.power-sonic.com/blog/what-is-a-gel-battery/ https://www.power-sonic.com/blog/what-is-an-agm-battery/ https://www.progressive-charge.com/lead-carbon-batteries.php https://www.energy.gov/energysaver/solid-state-batteries https://www.graphene-info.com/graphene-batteries https://www.victronenergy.com/blog/2015/03/28/matching-solar-power-with-battery-charging/ https://www.power-sonic.com/blog/understanding-the-different-types-of-lead-acid-batteries/ https://www.epectec.com/batteries/cell-comparison.html

#RVBattery #LiFePO4 #AGMBattery #RVElectrical #SolarForRVs #Boondocking #OffGridRV #RVLife #RVMods #RVTips #DeepCycleBattery #RVUpgrades #RVMaintenance #FullTimeRV #GoRVing #RVPower #BatteryTech #SodiumIon #RVLiving #RVSafety #EnergyStorage #VanLife #WolfTrekRVStuff